While basic engineering steels are generally unsuitable for aerostructures, our products find use in other areas relating to aircraft builds.

Steel's suitability for aerospace applications is dictated by performance. For example, aluminium and titanium are used extensively to build aircraft structures due to the alloy's impressive strength-to-weight ratio, while stainless steel is highly suitable for corrosive environments.

Engineering steels are not so specialised but still have their place depending on the make-up of the material and the intended application. Low carbon, medium carbon and alloy steels all find use along with heat-treated products, although these uses tend to be non-critical as there are better alternatives.

The aerospace sector represents unique challenges for engineering companies, and these businesses use various materials and alloys to create parts and structures, including general engineering steels.

Low-carbon steel finds use in producing bushes and safety wires, while medium-carbon steels are ideal for connecting rods and light forgings.

Heat-treated steels provide superior wear resistance and hardness and therefore are suitable for abrasive environments or ones susceptible to impact. Products include nitrided and carburised steels.

Engineering steels are highly versatile, simple to machine and weld, and relatively cheap compared to other alloy products.

Carbon steels offer a great material alternative in applications where strength is a requirement but where the application is not critical to the safety of the aircraft. Certain steel products are produced as aerospace-grade materials.

Steel represents a low-cost engineering alternative to more high-performance alloys such as aluminium and titanium.

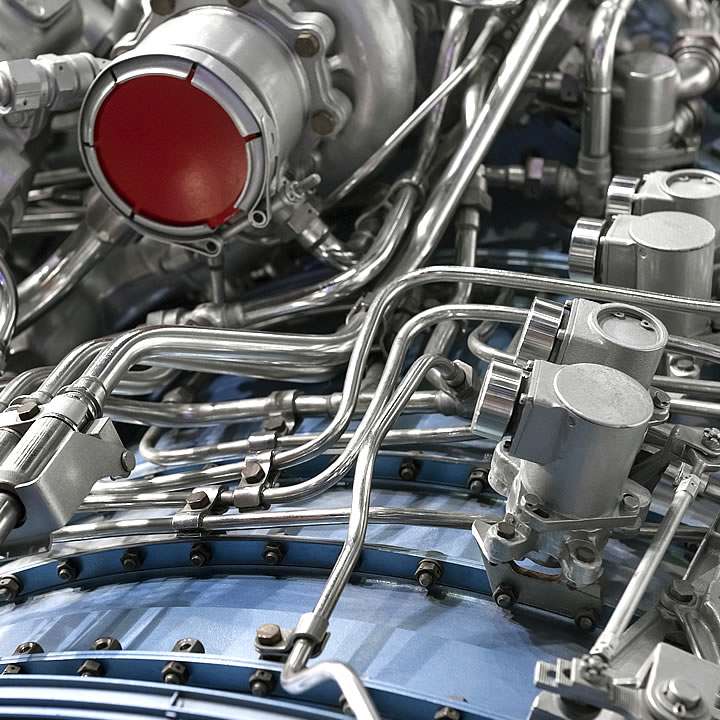

The aerospace sector uses engineering steels in a broad range of applications, from fasteners to connecting rods and forgings.

Steel is harder than many alloys and is, therefore, less likely to bend at elevated temperatures or under impact.