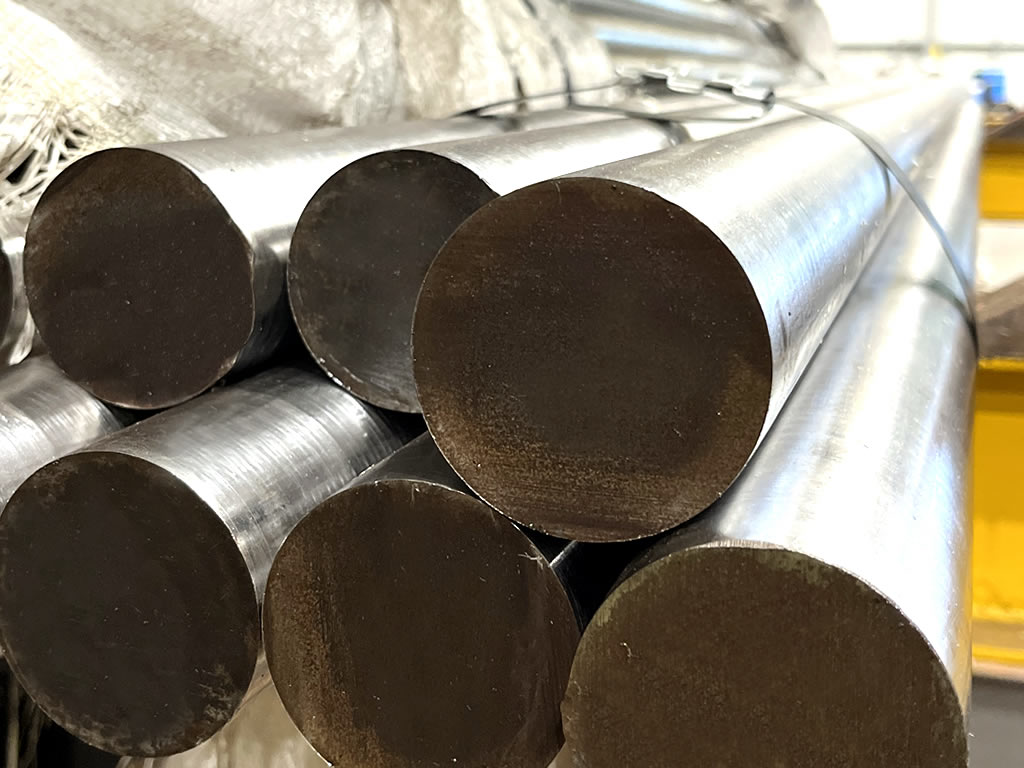

817M40 Steel (EN24)

817M40 is a low-alloy steel commonly used for applications requiring high tensile strength, toughness, and fatigue resistance.

It is also known as EN24, AISI 4340, or 34CrNiMo6. The composition of 817M40 steel typically includes carbon, chromium, nickel, molybdenum, and manganese.

Benefits:

- High strength

- Fatigue-resistant material

- Versatile

- Heat treatable

Aerospace Grade:

817M40 is a British aerospace-grade steel commonly used in the aerospace industry for high-strength applications. It is classified as a low-alloy steel. It is often called an 'aerospace-grade' steel due to its high-performance characteristics and ability to withstand demanding environments. This grade is also used in other industries, such as motorsports and oil and gas, where high strength and toughness are required.

Chemical Composition (weight, %)

| C | Si | Mn | P | S | Cr | Mo | Ni | |

|---|---|---|---|---|---|---|---|---|

| Min. | 0.36 | 0.10 | 0.45 | 1.00 | 0.20 | 1.30 | ||

| Max. | 0.44 | 0.40 | 0.70 | 0.035 | 0.040 | 1.40 | 0.35 | 1.70 |