27MnCrB5 Steel

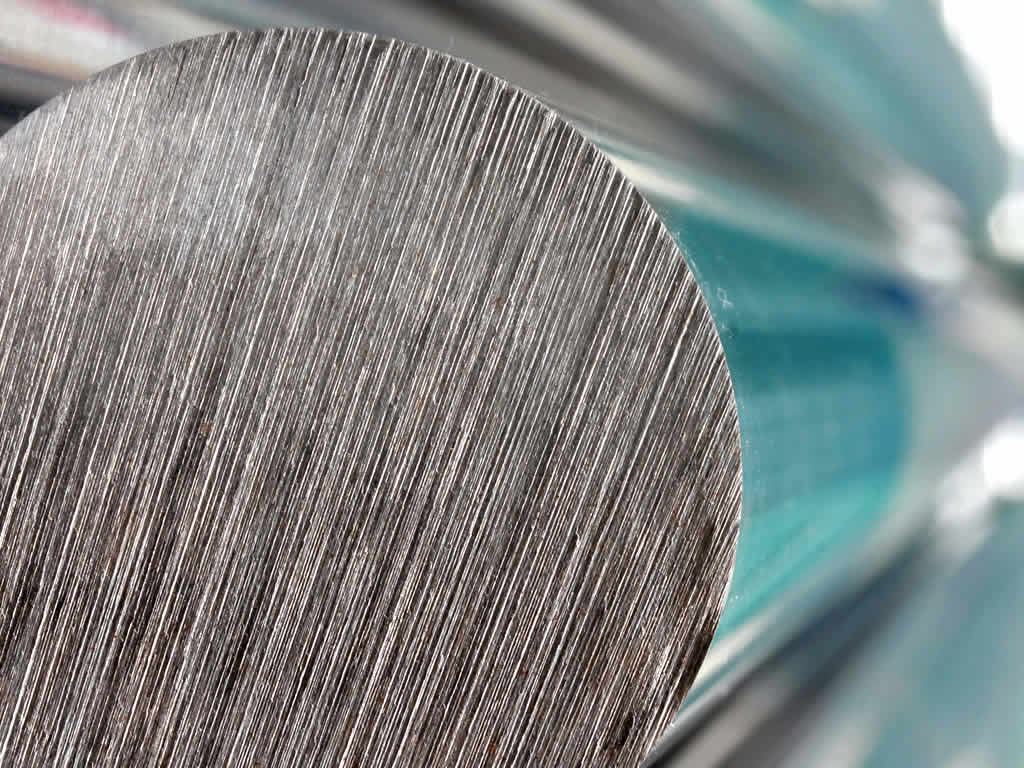

27MnCrB5 (1.7182) is a boron heat-treatable low alloy engineering steel that offers a cost-effective material solution compared to other steel grades.

The alloy benefits from high mechanical strength, making it suitable for high-stressed component production. The material also combines good toughness and hardness.

Applications:

- High tensile fasteners

- Suspension systems

- Crankshafts

- Gears and bearings

Introduction of Boron (B):

Adding boron (B) to the alloying process also improves wear resistance. These characteristics result in a highly versatile steel alloy which finds use in various engineering applications. 27MnCrB5 offers good machinability and weldability.

Chemical Composition (weight, %)

| C | Si | Mn | P | S | Cr | B | |

|---|---|---|---|---|---|---|---|

| Min. | 0.25 | 1.10 | 0.30 | 0.0008 | |||

| Max. | 0.30 | 0.40 | 1.40 | 0.025 | 0.035 | 0.60 | 0.005 |